Top 10 Rock Drill Attachment Accessory Options at WORD Rock Drills

10. Energy Chain

The longer your feed rail, the more important the addition of the energy chain becomes to the overall effectiveness of your machine. We offer a range of feed rail options from 6′ to 24′ for our Skid Steer and Excavator attachments depending on your specific project requirements. The addition of an energy chain is often recommended for any feed rail exceeding 12′.

9. Nitrogen Charge Kit

A common addition whenever a unit is equipped with a Doofor drilling motor, hydraulic clamp, or hydraulic breaker; this accessory comes in handy for routine maintenance of any unit with these features. These kits are available in three options that allow you to stock up on additional pieces that you might need in the field whenever accumulator maintenance is required. View Accumulator Charge Kits Here

8. Hydraulic Clamp

Making this accessory addition to your excavator or skid steer drilling attachment can really boost efficiency on the job site when dealing with hollow bar. This accessory is the ideal companion to your machine, assisting your team by quickly grabbing the coupling for quick unthreading.

7. Hydraulic Clamp and Breaker

A very helpful accessory whenever you are operating with casing, the addition of a hydraulic clamp and clamp breaker to your machine saves your guys in the field from the grueling work of wrestling with large pipe wrenches all day. The hydraulic clamp and clamp breaker accessory can easily unthread drill pipe/casing up to 8″.

6. Remote Angle Indication

An easy add-on to any excavator attachment purchase, the addition of angle indication to your remote will provide you with a digital readout of your drill positioning. This feature is particularly beneficial when you are on a job that requires specific angle positioning such as roof bolting, dewatering, and hollow bar installation.

5. Line Oiler

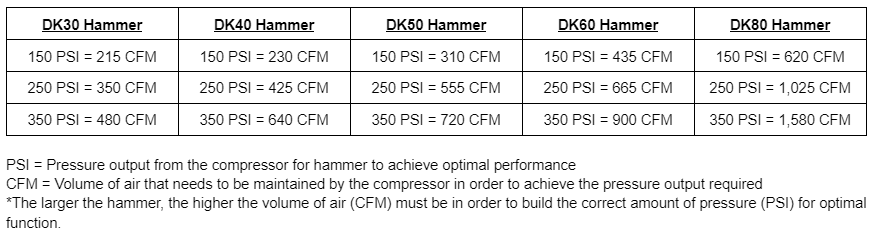

Available in two sizes, a line oiler is a much-needed accessory whenever you are drilling with a down-the-hole hammer. The line oiler allows for a regulated flow of rock drill oil to lubricate the airline while drilling and keep everything running smoothly. Learn More Here

4. Dust Collector System

One of the newer options available for WORD EX series attachments, this dust collector system is one step up from our very popular mist pump dust suppression system. Where our mist pump system uses water to dampen the amount of dust generated while drilling, this newer system collects the dust and pulls it away from the hole entirely. This option may be more favorable for your project if strict dust regulations are involved or in cold temperatures where water is likely to freeze.

3. Excavator Shipping Platform

Making the investment in an excavator shipping platform for a new or existing unit has many benefits. Equipped with a dedicated job box and forklift designations, this platform makes it easy to move your rock drill unit from one job to the next with everything that you need. Store spare parts, dedicated tools, remote control components, rock drill oil, and more in the job box to keep these essential items easily accessible throughout the project. In addition, this platform is ideal for storage between jobs to keep your unit off the ground.

2. Stabilizing Kickstands

Equip your crew with additional drilling stability with our SS Series kickstand. Most commonly used when drilling larger holes, these kickstands make drill operation easier by limiting the range of movement if the skid steer begins to bleed down during drilling.

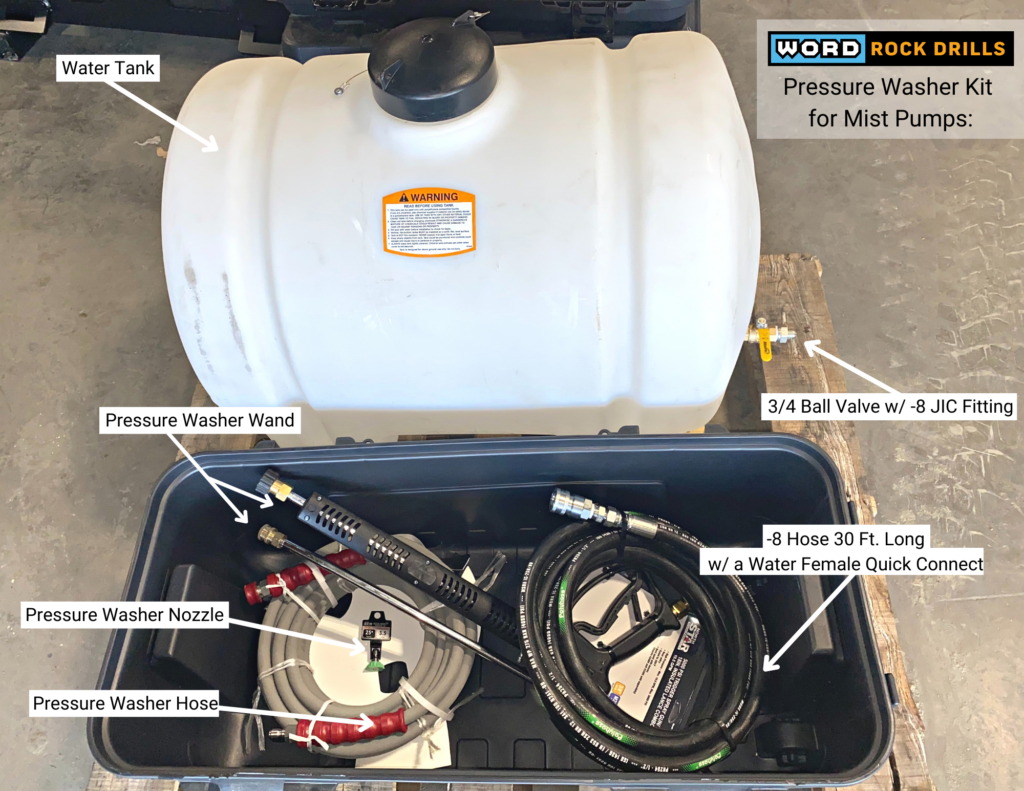

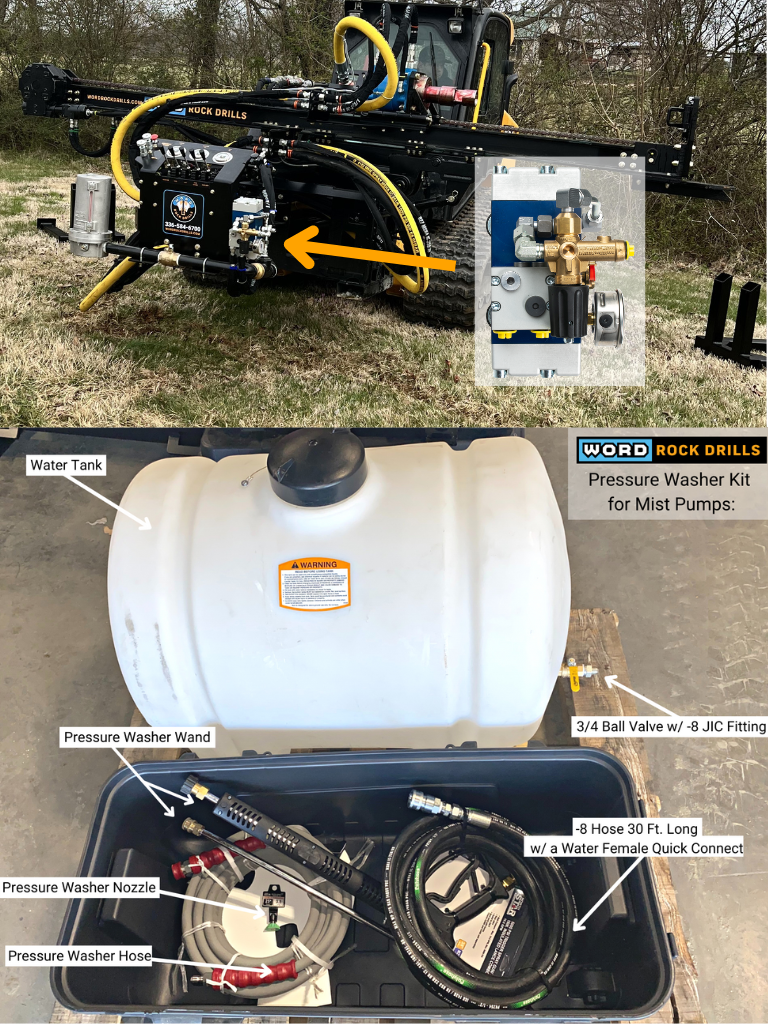

1. Mist Pump Dust Suppression Kit

One of our most requested accessory options, our water mist dust suppression system applies water while drilling to dampen down dust. Whether or not dust suppression is required on your job site, limiting dust can tremendously help your crew. In addition, the kit comes with a water tank and pressure washer wand, making it easy to clean your drill at the end of each day.